LADSIM is a fully

functional ladder logic design and PLC simulation software program that

incorporates the functions used in PLC ladder programming. LADSIM uses the PC

as a virtual PLC.

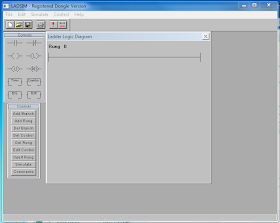

Figure 1. LADSIM Interface

There are three main screen of LADSIM:

1.

The Ladder Logic Diagram Window

This

is where the ladder code is displayed. Each time you add or edit a rung, the

result will be shown here.

Rung is serves as conditioning

for command input and output logic.

2.

The Controls box.

This

contains the ladder symbols that are used to create the ladder diagram. See

below for further details.

3.

The toolbar

This

includes the standard buttons of LADSIM and allows you to start a new diagram,

open an existing file, print, save and comment your ladder diagram.

You aso can apply your ladder code to run simulations in LADSIM. These simulations are:

1.

Traffic Light

Code must be written to control the

sequence of operation of the lights. A typical sequence could be : RED 'ON'

immediately After 2 seconds YELLOW 'ON' After 3 seconds GREEN 'ON' only After 5 seconds YELLOW 'ON' only After 1 second Restart Sequence. The task would be to code this sequence

in ladder logic and operate the lights accordingly.

2.

The Annunciator

In industry, plant conditions need

to be monitored and, if there are problems, a way of indicating these problems.

An indicator system of this type is called an annunciator. A typical alarm

system uses the following sequence to indicate a plant alarm condition to an

operator. System healthy - no indication. System in alarm - a flashing light

and audible alarm.

The annunciator in LADSIM must be programmed to allow

the correct operation.

3.

The Car Park

The diagram shows the layout of a

simple car park. It has an entry barrier and an exit barrier. The car park

itself has six spaces and a series of displays to indicate whether it is full,

has spaces or is empty, with a numerical indicator to determine the exact

amount.

Ladder code needs to be written that will allow cars

into the car park when it is empty or has spaces and to exit the car park

through the correct barrier. Ladder code must also be written to control the

display boxes in the centre of the screen.

4.

The Lift (Elevator)

A program is required that will drive

the lift from one floor to the other on a signal from the call button. Safety

is essential and we must be careful not to have anything obstructing the

operation of the doors.

5.

The Drinks Machine

When a coin is placed into the slot,

the user should be able to select his or her favourite drink or reject the

coin. It is important to ensure that

the coin cannot be rejected once a drink has been selected or that selecting a

drink disables all of the other drink buttons.

6. The Packing Line

The packing line carries boxes of

different sizes which need to be separated into their relevant sizes.

Which direction the boxes go is decided by using the

input sensors IP0 and IP1. If a box is short, only one of the inputs is energised

at any one time. If it is a long box, then both inputs will be energised. These results can then be used to activate

the correct solenoid and the direction of rotation of the circular plate.

7.

The Bottling Plant

The graphic is an overview of a

simplified bottling plant with a filling station and packing area. Bottles are

fed along the first conveyor, conveyor 1, into the filling station. The bottles

must be stopped and filled with milk and then have a cap placed on them. Once

accomplished, they go onto conveyor 2 where the cap is screwed on tight. They

are finally stacked in the stacker area where they are pushed onto conveyor 3.

References:

Imelia Rizki Lestari

No comments:

Post a Comment