112111221

TI-35-INT

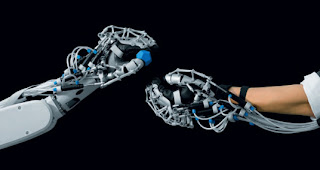

Robot Arm

An

industrial robot can be dissected into five major components – a robotic arm, controller,

drives, end effector, and sensors. Robot arm is one of the important part of

industrial robot especially in industrial automation. Robot arm can change the

human for

doing some dangerous job or job that must do very quick, difficult, safe, and very little mistake or something that cannot or impossible done by a human. Nowadays robot arm is one of the important part in manufacturing company on their plant. Not only manufacturing I think, but also some medicine firm use robotic arm to do the experiment, like you can see at Festo website, that robot arm doing some process to move chemical liquid or something like that to minimize mistake like shocks or maybe fallen down that will dangerous to human.

The robotic

arm component of an industrial robot usually contains six axes of motion,

although some models have more or less depending on the application they were

designed for. The robotic arm makes up the majority of the system and is often

the focal point. The robotic arm houses several other components including

wiring, cables, and drives. Typically, the larger the robotic arm, the higher

the maximum allowable payload.

How to made arm robot?

Shoulder is

the stationary based where the component is attach. The engineer first make the

design on the computer using CAD (Computer Aided Design) to get very

intelligent. Then to make the based they use computer guided press to bench and

welding. Next painting the casing using powder paint and electrostatic process

to guarantee ferro coat so the casing will like a magnet. After that making a

user diagram to illustrate how the arm robot will move.

Then create

the robot arm hand, first making the gripper which is function is to grasp and

carry the object. The material used to cover it is an aluminum. Also they

assembly the printed circuit board (PCB) that will control the robotic arm

movement. Them they assemble the electrical component to the base. And other

component like gear, shaft.

Then create

the robot arm hand, first making the gripper which is function is to grasp and

carry the object. The material used to cover it is an aluminum. Also they

assembly the printed circuit board (PCB) that will control the robotic arm

movement. Them they assemble the electrical component to the base. And other

component like gear, shaft.

In the arm

shoulder system, they install system of pulleys, which consist 2 plastic wheels

in several axel and rubber belt running between them. The belt in the wheel

rotate the wheel and make the robotic arm move. Each robotic arm is programmed

to act several task, and move like humans arm. They installed the cable to the

electrical based to make move the shoulder. After that they assembly and screw

the entire arm to the base.

They linked

the wire from circuit board on the base to the every motor in the shoulder, but

the wire must be bounch together. After all the wire installed correctly, they

test the wheel and gear to make sure they move. Then they set up the gripper,

where the shaft and the gear system operate it. Turning the gear one way opened

it, and turning the gear in another way will closed it. After there’s running

well, they assemble it to the shoulder arm. Plugin the motor to the circuit

board.

The board is

look like mother board on our PC, all of the component install on it from the

circuit until the controller like the processor that control anything connected

to the circuit.

Most robot

is programmed, so we can easily change the program depend the use of that

robot. For the employee robot is the ideal workers because they don’t need

rest, laugh, sick, food and drink and can minimize the cost significantly for

the long term. And the productivity is constant.

source :

.jpg)

This is the first time I am visiting your website. I would like to tell you that I am genuinely engaged by reading your blogs. Keep up the good work! robotic arm manufacturers

ReplyDeleteGreat blog, learned many things about welding machines from this blog, very informative. Pacific weld is one of the best places to buy welding machine in India.

ReplyDeleteAutomated Manufacturing System

Manufacturing Automation

Spm Machine Tools

Welding Robotic Arm

Great Yuva Welding Machines

Seam Welding Machine

Nice Post Very useful & informative

ReplyDeleteVertical conveyors

Asrs Warehouse

Palletising Systems

Pick to Light Put to Light

Automated Guided Vehicle systems

supply chain automation company

Automated Guided Vehicle

Smart Warehouse Management System

Industrial Automation Companies in Pune

Stretch Wrapping Machine

Industrial Racking